Supply chains have become more complex, the need for global temperature-controlled supply chain management solutions has intensified. With the benefits of globalization also comes significant challenges and responsibilities, and one of those challenges is ensuring the authenticity and quality of materials moving through the supply chain. As such, when dealing with temperature sensitive and highly regulated products such as pharma, biotech, and for cold chain logistics providers, informed real-time decisions need to be made on a daily basis.

Ensuring product quality, security, and compliance from start to the last-mile is crucial. Operating across many regions means that all stakeholders not only have to comply with global regulations, but also comply with local customs and varying environmental conditions. Therefore, ensuring a global temperature-controlled supply chain, requires a more strategic approach to supply chain management. The security implemented must also provide advanced visibility and flexibility to cope with these challenges.

WEIGHING THE RISKS

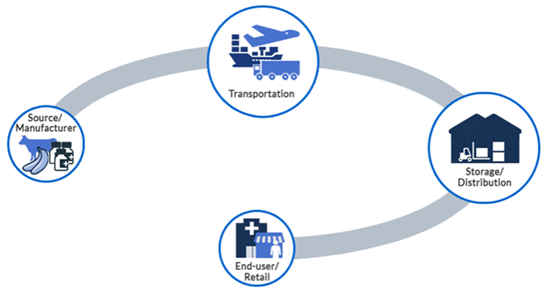

Fundamentally, temperature-sensitive items such as meats, vaccines, drugs, plants, and chemicals require temperature-controlled environments from the time they are manufactured until they reach the end user. The cold chain is established to keep the quality of these types of products in check as they travel to the end user. Within the pharmaceutical and life sciences industries, cold chains require medicines, vaccines, and other products in temperature-controlled packaging to maintain strict temperature boundaries.

For example, most vaccines need to be stored between 2 to 8°C (36 to 46°F) and temperature outside this range will compromise the vaccine. Similarly, temperature control is a critical food safety element, as it helps reduce spoilage and prevent foodborne diseases. Fresh produce must be kept at 0 to 16°C (32 to -60°F) or colder, while frozen and deep-frozen foods must generally be kept at 0 to -25°C (32 to -13°F) or colder. It is clear the ability to actively measure, monitor, and record data is a critical aspect of temperature management and a requirement for regulatory compliance.

Understandably, keeping the temperature consistent throughout the cold chain process can increase one’s blood pressure but tracking and monitoring does not have to be an issue with today’s options. A key consideration for product quality, integrity, and security is deploying embedded advanced monitoring and tracking devices while product is being transported. The movement of product through the cold chain can involve various types of transportation, various load amounts and distances spanning across the city or the continent— All of these factors make it important to implement the right solution to meet these obligations with confidence.

RISK MITIGATION

A simple and proven cost effective solution we offer those who manage cold chains is our NIST traceable temperature and data logging tags. Used in conjunction with our real-time tracking devices, the logged data is communicated and then transmitted for review on our Track Secure platform.

The Tyden trackers and logging tags not only allow workers to keep an eye on the temperature in real-time, but also provides alerts which may include product diversions and geo-fencing. Within our TydenBrooks cloud-based platform you have complete visibility of all your shipments with an unlimited data storage capability for later use to export data to CSV or PDF formats.

Once setup is complete, users can securely monitor parameters 24/7, control alarms remotely, view data logging history, run reports in real time, and give access to other team members. No local software is required to use our cloud-based data interface. Mobile push notifications, emails, or texts for out-of-range conditions come standard.

LEADING THE WAY – SECURING THE WORLD

As trusted experts of all thing’s cargo security related since 1873, TydenBrooks will ensure our customers are ready to meet the demands of today’s cold chain requirements. Whether you need real-time tracking and monitoring solutions or mechanical high security seals we supply proven multi-layered security strategies tailored to your needs.

If you are interested in learning more about our latest innovations such as our advanced tracking and monitoring solutions, get in touch for a free no-obligation shipment consultation and live demonstration or contact us directly at 1-800-458-SEAL.